THE UNFLATTERING TRUTH ABOUT “1-DAY ” COATING SYSTEMS

In recent years, “1-day polyurea-polyaspartic” concrete coating systems have become increasingly popular among homeowners looking to renovate their garage floors. These systems are marketed as quick and easy to install, with contractors claiming to be able to complete the job in just one day. However, according to an article by GarageFloorCoating.com (Polyurea-Polyaspartic 1-Day Systems: Do They Work), these claims may not be trustworthy.

What are Polyurea and Polyaspartic Coatings

A polyurea is a liquid coating often used in industrial and commercial settings to protect surfaces. These coatings have extremely short cure times and are durable enough to coat roofs, foundations, decks, and other surfaces. A polyaspartic is chemically similar (it’s an “aliphatic polyurea”), but has been engineered to cure slower than a polyurea (…just not as slow as an epoxy).

This “Goldilocks” quick (but not-so-quick) curing capability is one reason why polyaspartic coatings are regularly used in the concrete coatings industry. This, and the fact that a polyaspartic provides extreme UV, chemical and impact resistance, makes them excellent choices as garage floor coatings. A quality (100% solids) polyaspartic can protect against staining from automotive fluids, hot-tire transfer, bumps, and fading due to sunlight exposure.

Polyurea-Polyaspartics: An Achilles Heel

Clearly, polyurea-polyaspartics have several extraordinary qualities that make them perfectly suited for use in coating systems. Unfortunately, they have an Achilles heel…they don’t bond well to concrete in the presence of moisture. They cure differently than an epoxy and can only be applied as wafer-thin coats (conversely, and epoxy can be applied thickly).

If the concrete’s moisture (as measured with a moisture meter) is medium to high, applying a wafer-thin polyurea-polyaspartic coat direct-to-concrete will be problematic. As the hydrostatic pressure builds in the concrete, these coatings tend to peel (delaminate). It may take 1 year, 2 years…or 5 years…but if the hydrostatic pressure is sufficient, delamination will occur. Polyurea-polyaspartics are simply not meant for “direct-to-concrete” use in the presence of moisture. And most concrete has moisture.

Experienced (honest) contractors know this and don’t gamble with your floor coating. They use a slower-curing, moisture-mitigating epoxy as the primer coat. They only apply the polyurea-polyaspartic as a clear topcoat. But because the epoxy primer cures slower than a polyurea-polyaspartic, the installation process takes longer than one day…it typically takes two.

The Costly “1-Day” Shortcut

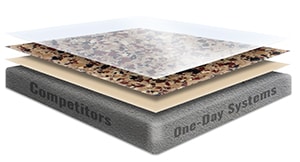

“1-day” system contractors, on the other hand, take the gamble to complete the job in just one day. They apply a thin coat of 70%-plus solids polyurea-polyaspartic (not 100% solids) direct-to-concrete. Bad idea…but “1-day” contractors have an ace up their sleeves. They simply add a “warranty exclusion” that states their coatings are not warranted against…well, pick one…”moisture-related issues”, “hydrostatic pressure”, “moisture vapor transmission”…the list goes on.

But when the “1-day” coating system delaminates, the contractor simply invokes the warranty exclusion to avoid liability. This practice is why homeowners should be cautious when considering “1-day” concrete coating systems.

How do you protect yourself? Ask to see the warranty exclusions!

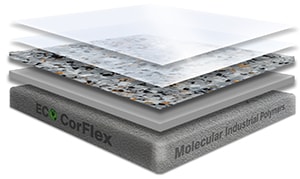

Ours

Theirs

An Honest Alternative

In contrast, quality contractors will use a variety of coating products, including epoxies, polyurethanes, and polyurea-polyaspartics, depending on the job requirements. They will also use the appropriate primer coat to mitigate moisture and ensure a strong bond between the coating and the concrete.

At Garage Floor Coating Rochester NY, we take pride in our thick garage floor coatings, which are guaranteed against moisture-related conditions (and tire staining). We use industrial-grade polyurea-polyaspartic coatings as clear topcoats only, never as direct-to-concrete primers. Our full-chip, mica stone concrete coatings incorporate an ultra-thick, 100%-solids moisture-mitigating primer coat, a full-chip mica-infused broadcast, and two (not one, like “1-day” systems) 100%-solids polyurea-polyaspartic topcoats with anti-skid to prevent slippage. You’d think these systems would cost so much more than a thin “1-day” system…but they don’t.

Our coatings are over 35 mils thick (almost double a “1-day” system), providing superior protection against moisture-related issues and “hot tire transfer,” the leading causes of coating system failures. Our full-chip mica coatings are simply thicker, stronger, and better looking.

A Real Warranty

Homeowners should be wary of “1-day” concrete coating systems that promise quick and easy installation. These systems gamble with a “polyurea-polyaspartic direct-to-concrete shortcut” that can lead to coating failures and costly repairs. Quality contractors use the appropriate products and installation methods to ensure a long-lasting, attractive, and durable garage floor. At Epoxy Flooring Inland NW, we take pride in providing our customers with beautiful, industrial-grade concrete coatings…backed by a (real) lifetime warranty.